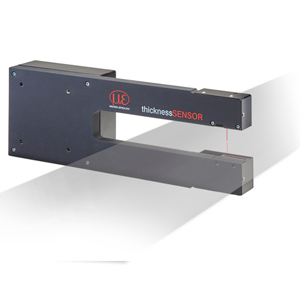

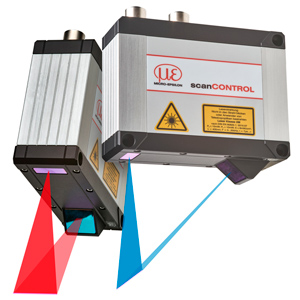

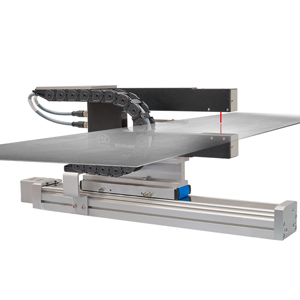

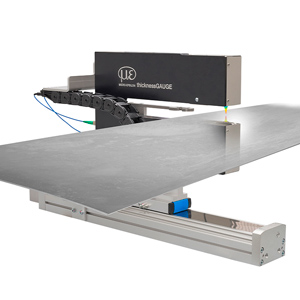

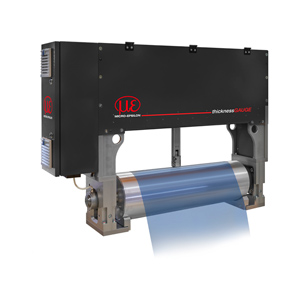

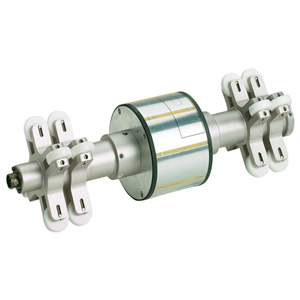

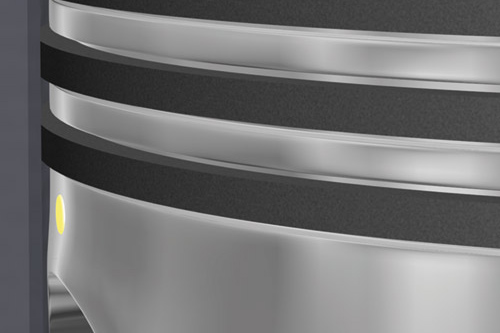

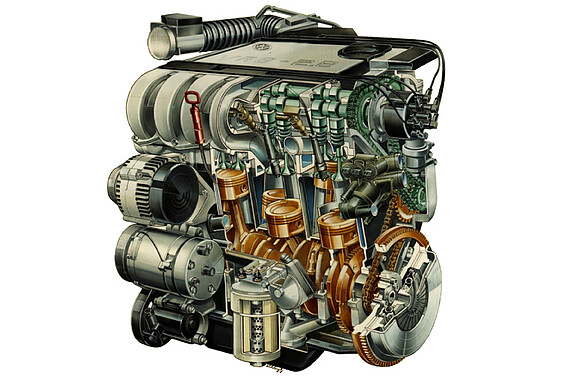

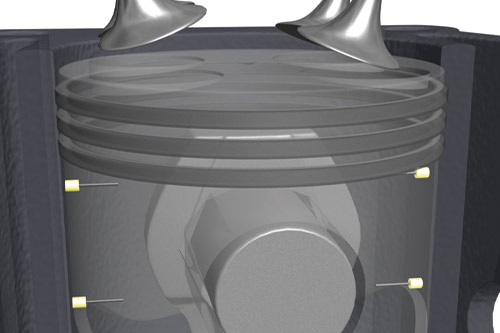

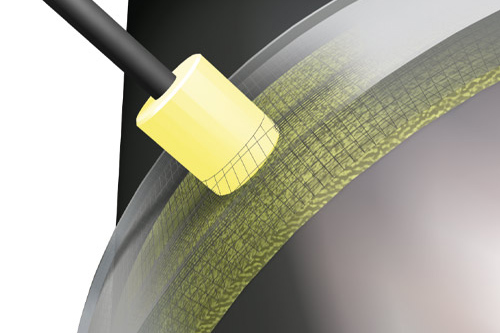

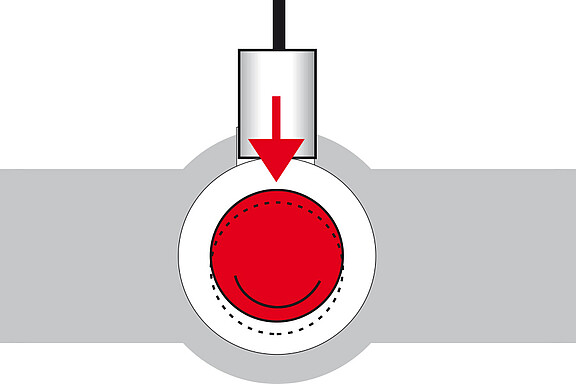

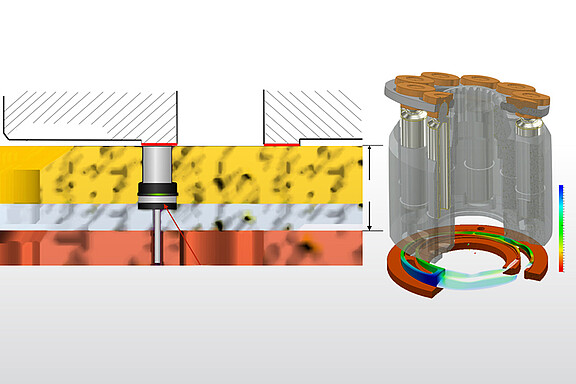

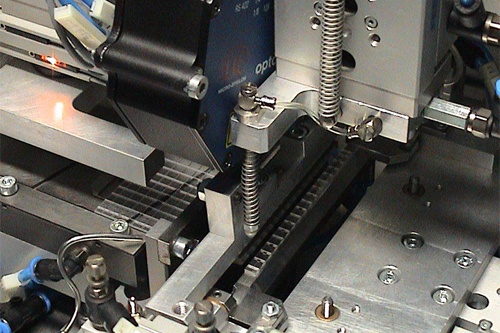

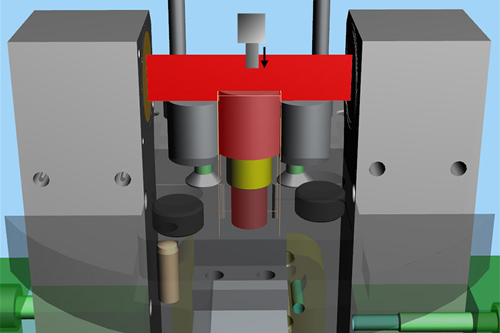

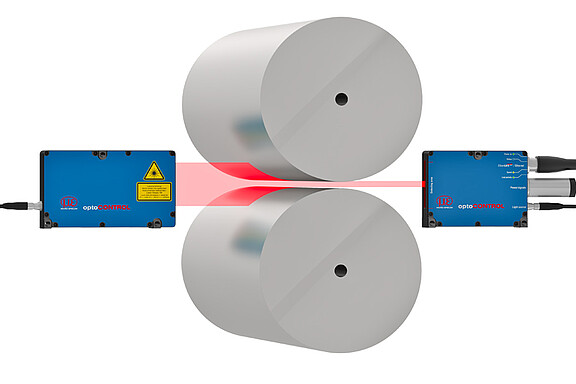

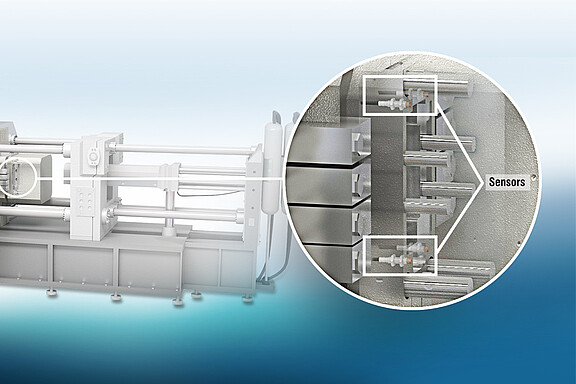

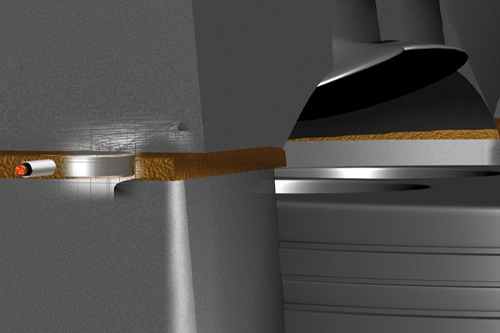

Gap, roller gap, roller convexity

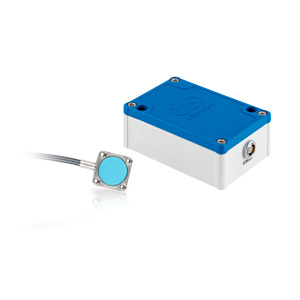

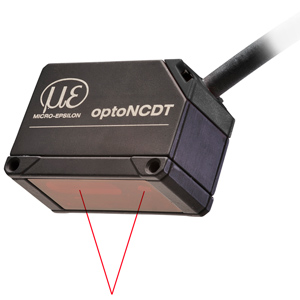

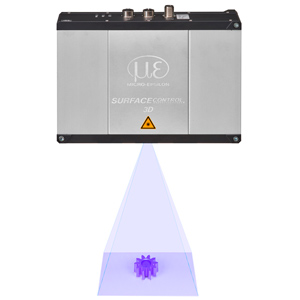

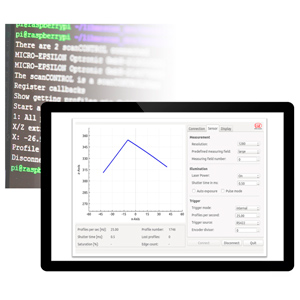

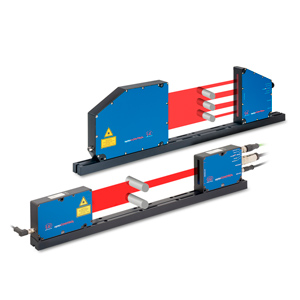

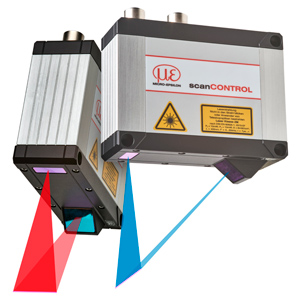

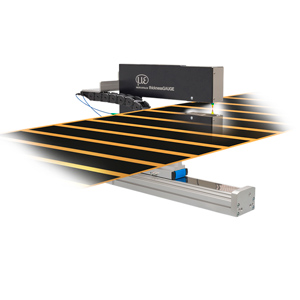

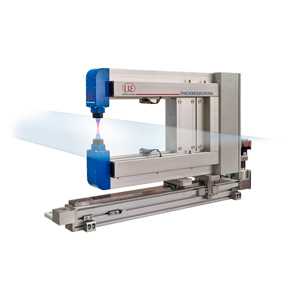

If two object edges are joined together, a gap always remains. If the gap has to satisfy technical or visual requirements, the course with respect to the size must be checked. If the gap should be measured completely, laser scanners in the scanCONTROL series are ideally suitable for this. Point laser sensors in the optoNCDT group are also used for precise gap measurement over a track.