Hot mill

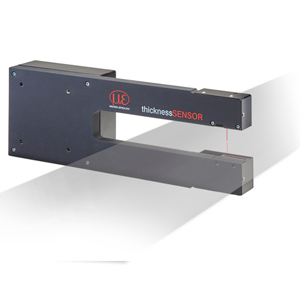

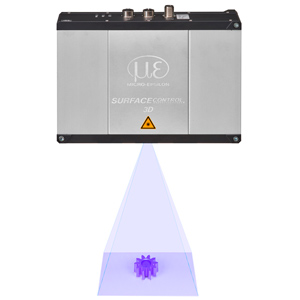

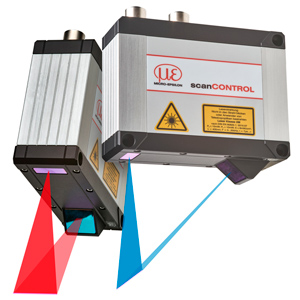

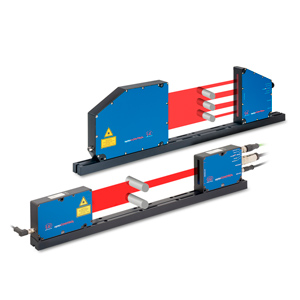

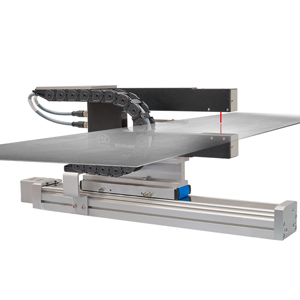

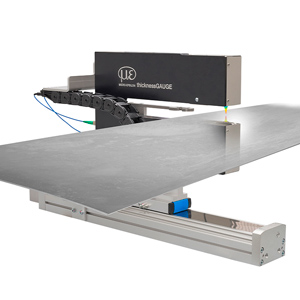

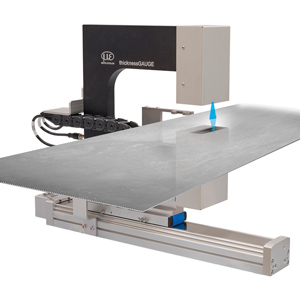

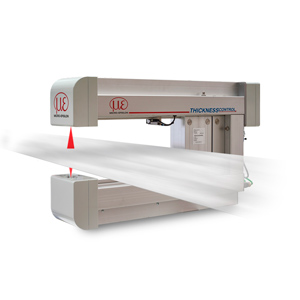

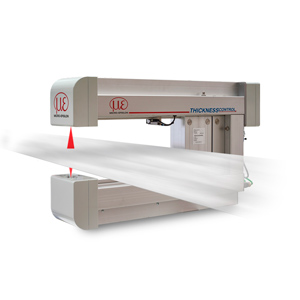

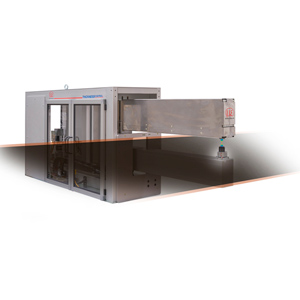

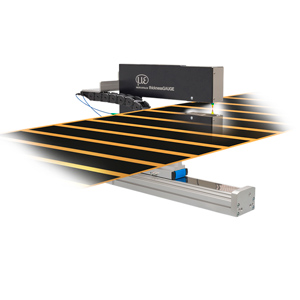

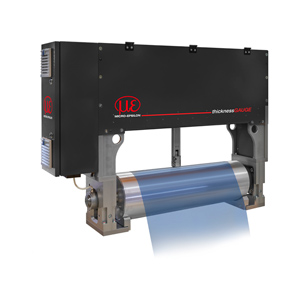

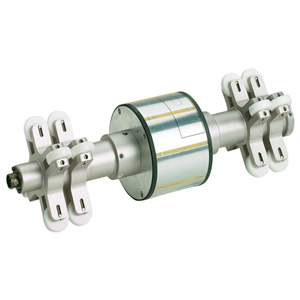

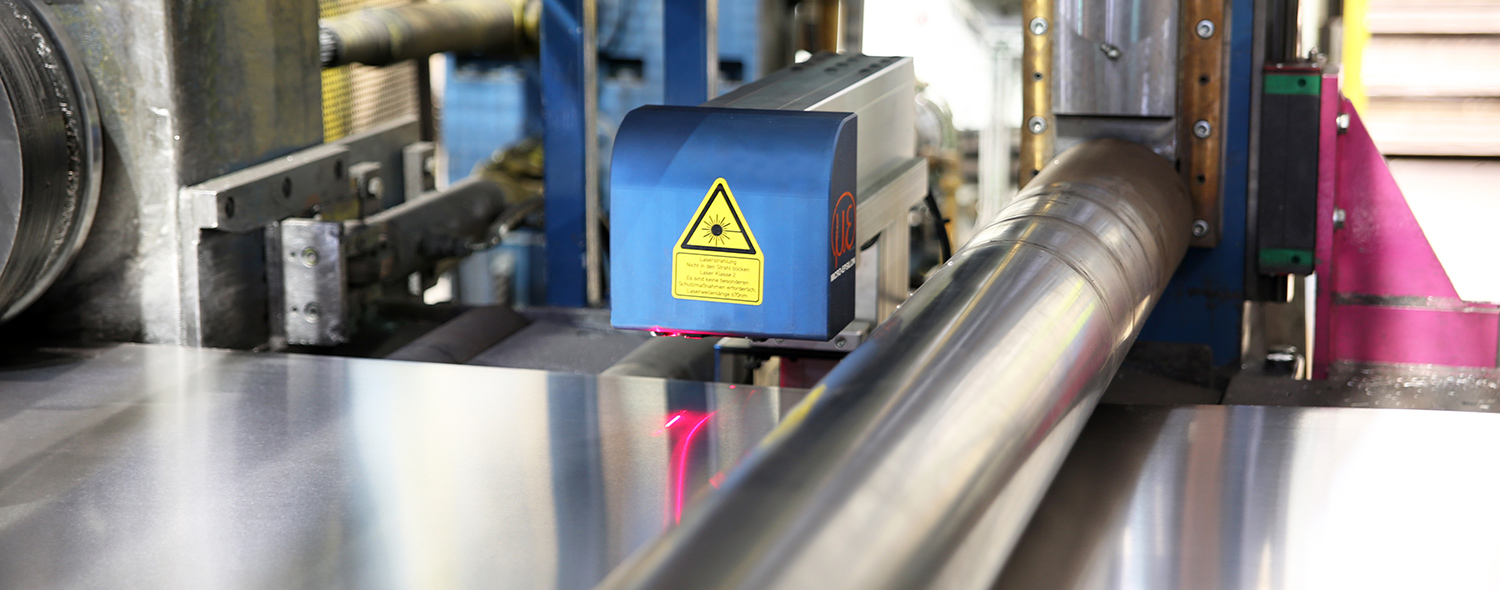

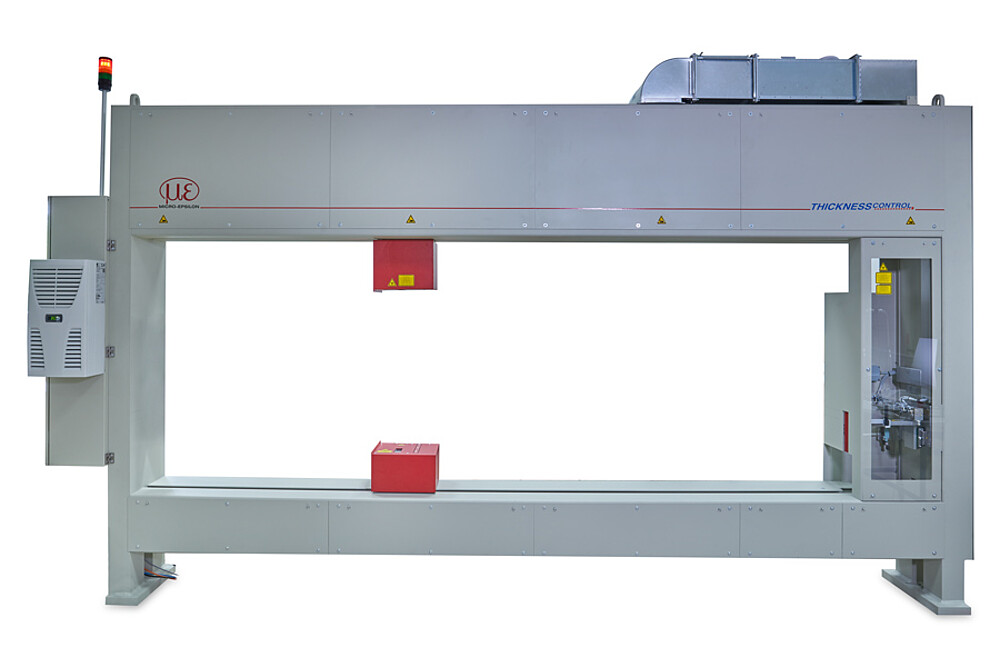

Typical applications in aluminum hot strip mills are the measurement of the thickness profile behind the roughing stand, the center thickness before the reversing finishing stand and finally after the reversing finishing stand the width, the thickness as well as the thickness profile with wedge shape and crown. For these measurement tasks, Micro-Epsilon offers thicknessCONTROL MTS 9201.LLT optical thickness measuring systems in O-frame design and the thicknessCONTROL MTS 9202.LLT in C-frame design. These systems impress with their high precision even across wide thickness variances, as well as their robust design to meet the challenging conditions found in hot rolling environments.

Detaljer

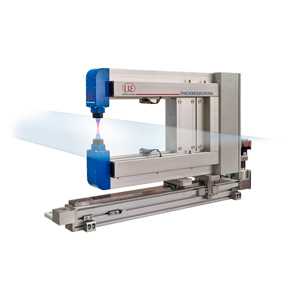

- Patented technology for compensation of thermal effects on the mechanical frame

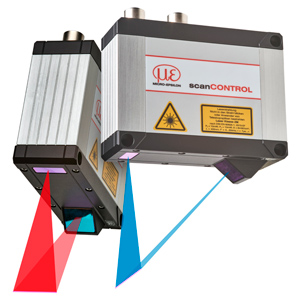

- Special sensor technology with double camera 400 mm measuring range, accuracy +/-10 µm

- High-performance cooling system for material temperatures up to over 600° C

- Pneumatic protection device of the optics

- Material/alloy-independent calibration and measurement

Thickness measurement in the hot rolling mill with thicknessCONTROL MTS 9202.LLT C-frame system and thicknessCONTROL MTS 9201.LLT O-frame system

The advantages of thicknessCONTROL MTS 9202.LLT come into their own especially with high thickness targets or large variations in thickness during the rolling process.

- Suitable for material thicknesses from 400 mm to 1 mm

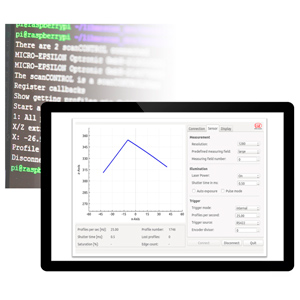

- Thickness or thickness profile measurement, selectable by software

- Integrated calibration to compensate for thermal effects

- Excellent ratio of measuring range to precision

- Optional integration of air purge for steam and emulsion