Defektdetektering på olackerade karosser (BIW)

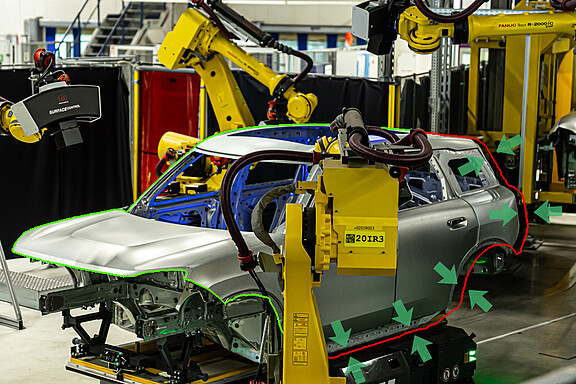

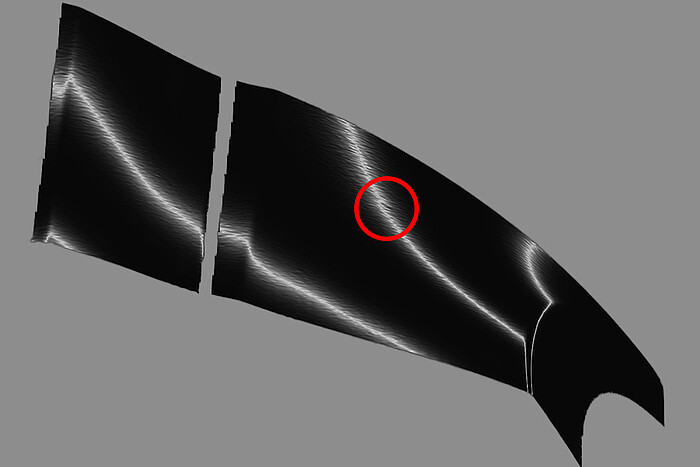

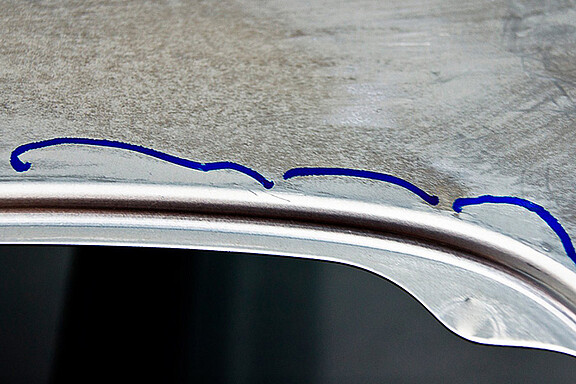

Mätsystemet surfaceCONTROL Automotive används för helautomatiserad defektdetektering på olackerade karosser. Systemet nyttjar principen med ströljusprojektion på diffust reflekterande ytor och detekterar med hjälp av inlärande förfaranden lokala formfel som glättmärken, sprickor och insjunkningar med hög precision och reproducerbarhet.

Systemet omfattar sensorteknik, robotteknik, dator, programvara samt gränssnitt och konfigureras individuellt för kunden. Antalet sensorer och robotar kan skaleras flexibelt – perfekt för olika takttider och genomströmningskrav.

Speciella egenskaper

- högexakt detektering och lokalisering av defekter

- hög täckning på krökta ytor (dörrhandtag, designkanter, kantområden)

- kompatibel med konventionella industrirobotar

- flexibel konfiguration av celler

- koncernövergripande överförbarhet till alla modeller

- komplett integrering: sensorteknik, robotteknik och automatisering från en enda leverantör

100 % inspektion med hög detekteringsfrekvens

surfaceCONTROL Automotive övertygar med en hög defektdetektering på olackerade karosser inom fordonsindustrin. Inspektionssystemet uppnår en enastående yttäckning på ≥ 97 %. Därmed utförs inspektionen ända in i kantområdet. Även designkanter och kraftigt välvda områden som exempelvis fördjupningar vid dörrhandtag registreras tillförlitligt och beaktas vid defektdetekteringen. Även defekter på avdragna områden på de olackerade karosserna kan fastställas med surfaceCONTROL Automotive.

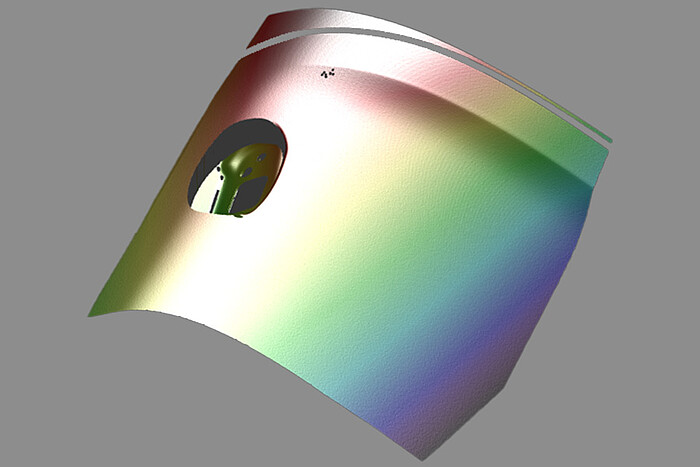

Integrerad 6D-lägeskorrigering

Mätsystemen surfaceCONTROL har en integrerad 6D-offsetkorrigering som automatiskt kompenserar lägesavvikelser hos karossen. Därigenom görs mätningarna snabbt, exakt och med hög repeterbar noggrannhet, även med mindre lägesavvikelser.

Tack vare den helautomatiska beräkningen av objektläget i rummet anpassar systemet mätpositionerna på lämpligt sätt och korrigerar även öppningsvinkeln för dörrar och luckor.

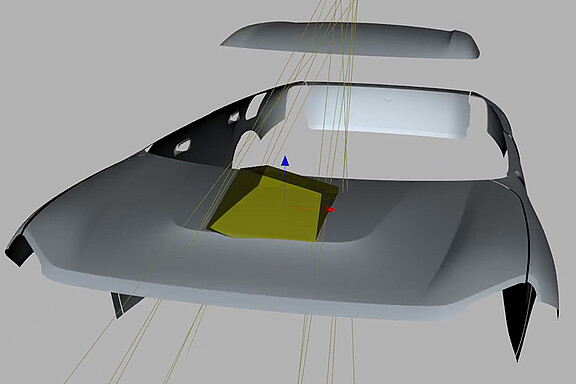

CAD-baserad simulering för effektiv inrättning

Den robotbaserade inspektionslösningen nyttjar moderna simuleringsförfaranden baserat på den olackerade karossens CAD-modell. Redan under planeringsfasen gör den virtuella avbildningen av givaren det möjligt att utföra en exakt analys av synfält, mätavstånd och eventuella skuggningar. På så sätt kan optimala monteringspositioner och rörelseförlopp definieras utan att fysiska prototyper måste användas.

Simuleringen ger en hög säkerhet för planeringen: kritiska ytområden identifieras i ett tidigt skede, provningsstrategier kan testas på ett verklighetsnära sätt och integreringen i existerande produktionslinjer förenklas avsevärt. Dessutom kan systemet snabbt anpassas till nya modeller och varianter. Resultatet är effektiva, reproducerbara inspektionsprocesser med minimalt uppställningsarbete och hög mätningskvalitet.

Programvaruverktyg för dataanalys

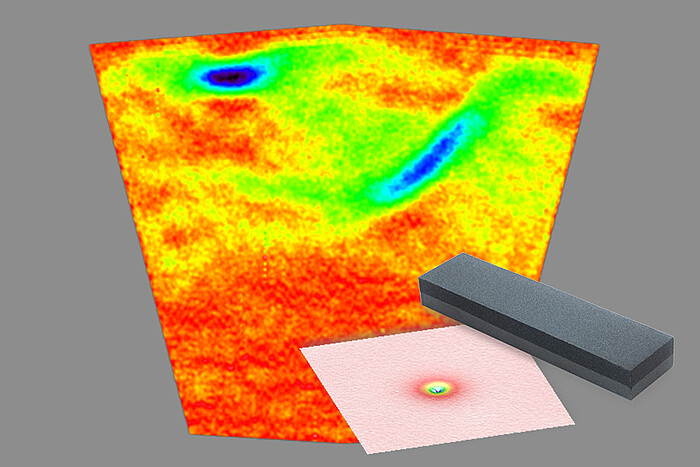

Individuell klassificering av fel med toleranser

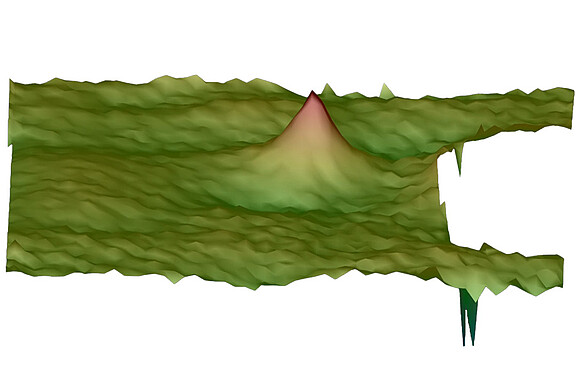

Genom generering av äkta 3D-data tilldelas detaljerade 3D-egenskaper som diameter, yta och höjd till varje fel. Toleranser parametreras enligt kundens specifikationer och kan anpassas snabbt — perfekt för införande i flera fabriker och för flera modellserier.

Samtliga data sparas i en XML-fil och överlämnas till användaren. Det gör det möjligt att utföra en sömlös integrering av resultaten i existerande kvalitetssäkringssystem.

Optimerat karossflöde & målinriktat efterarbete

Den exakta identifieringen av de mest skilda formfel på ytan gör det möjligt att optimera processer för efterbearbetning. Tack vare den extremt höga täckningen blir dessutom direktkörningar möjliga, vilka inte längre måste inspekteras manuellt.

Därigenom bidrar surfaceCONTROL mätsystem till en tydlig effektivitetshöjning inom fordonsproduktionen.

En kontaktperson för hela projekteringen

Som generalentreprenör sköter Micro-Epsilon hela projekteringen. Detta omfattar förutom mätteknik robotkonstruktion, planering, integration i befintliga styrsystem och implementering av data- och mjukvarugränssnitt. Du får också paket för regelbunden service och underhåll av anläggningar.