New color space for even more precision in color recognition

The colorSENSOR CFO250 color sensor series is being expanded by the LCh color space. The latter and the segment tolerance increase the match with human color perception by a further ten percentage points. This ensures extremely precise color recognition. In addition, hue and saturation can be adjusted separately.

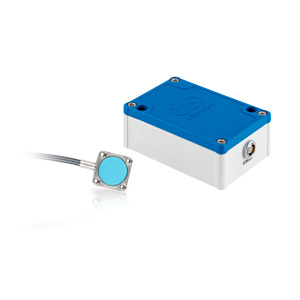

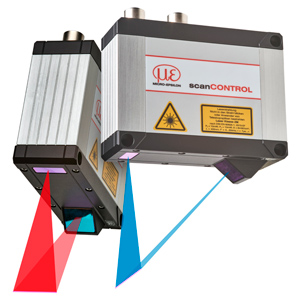

Due to the high accuracy and a measuring rate of up to 30 kHz, controllers from the colorSENSOR CFO250 series are primarily used in highly dynamic inline measurements – for example for 100% quality control in print mark detection or batch testing. Previously the CFO250 has been available in the color spaces XYZ, xyY, L*a*b*, L*u*v* and u'v'L*, and now also with LCh color space. Users benefit from a 10 percent higher correspondence of color perception with human vision compared to the L*a*b* color space and thus maximum color accuracy. The LCh color space is also very well suited for the intuitive display and editing of colors.

Structure and properties of the LCh color space

The LCh color space consists of the components luminance (L), chroma (C) and hue (h). L stands for brightness (luminance) in a spectrum from 0 (black) to 100 (white), C for saturation (chroma) with a spectrum from 0 (low saturation) to 100 (high saturation) and h for the color tone (hue) from 0° to 360°, for example red, green or blue. When using the LCh color space and the segment tolerance, the color perception increases by 10 percent compared to the L*a*b* color space. The colorSENSOR CFO250 quickly and reliably compares the taught colors with the current measured value and evaluates them according to OK or NOK. In addition, the raw data can be transmitted directly to a PLC or machine system at up to 500 Hz via a UDP, RS232 or USB interface. Corresponding edge or level triggers also control how long or how many measured values are output.

Memory for up to 254 color groups

The large color memory for different test batches offers a particular advantage. The controller is also ideally suited for harsh environments thanks to its robust aluminum housing and IP65 protection class. It can be commissioned and calibrated quickly and easily via a user-friendly web interface. The colors can also be conveniently taught in via the intuitive web interface. 254 color groups with more than 320 individual colors can be taught in the CFO controller. The color groups are used among other things to increase color accuracy.