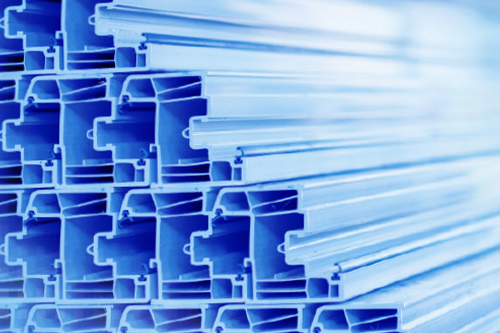

Plastproduktion

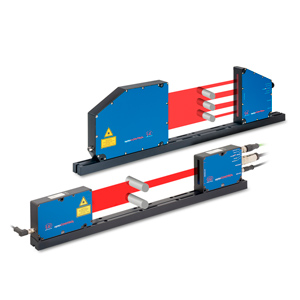

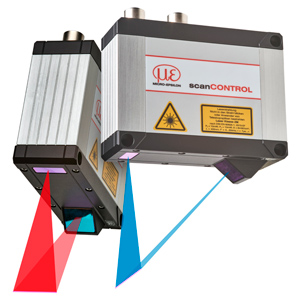

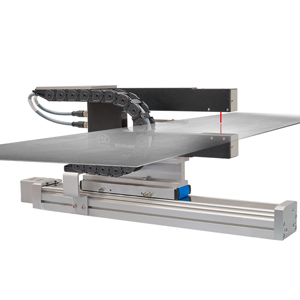

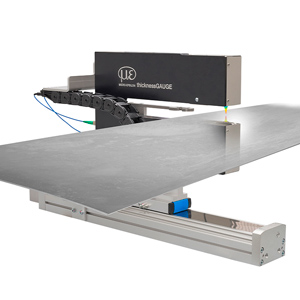

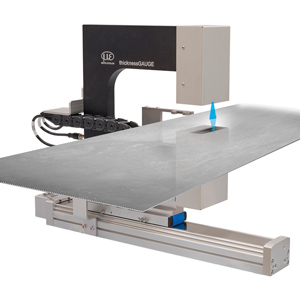

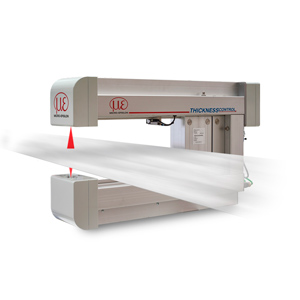

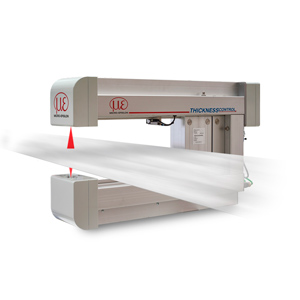

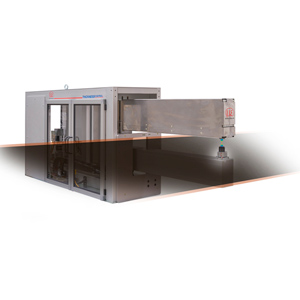

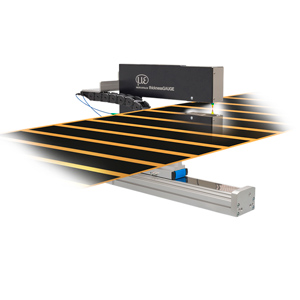

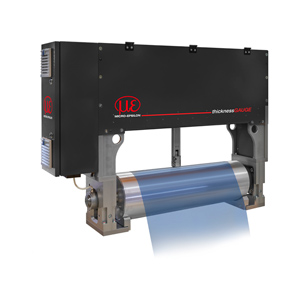

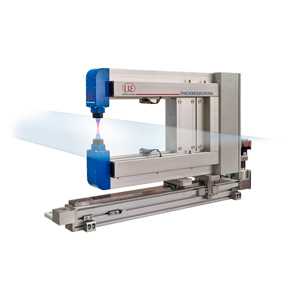

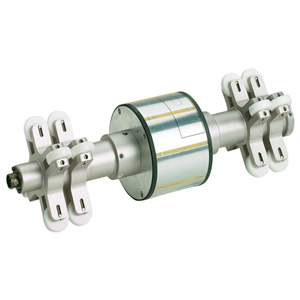

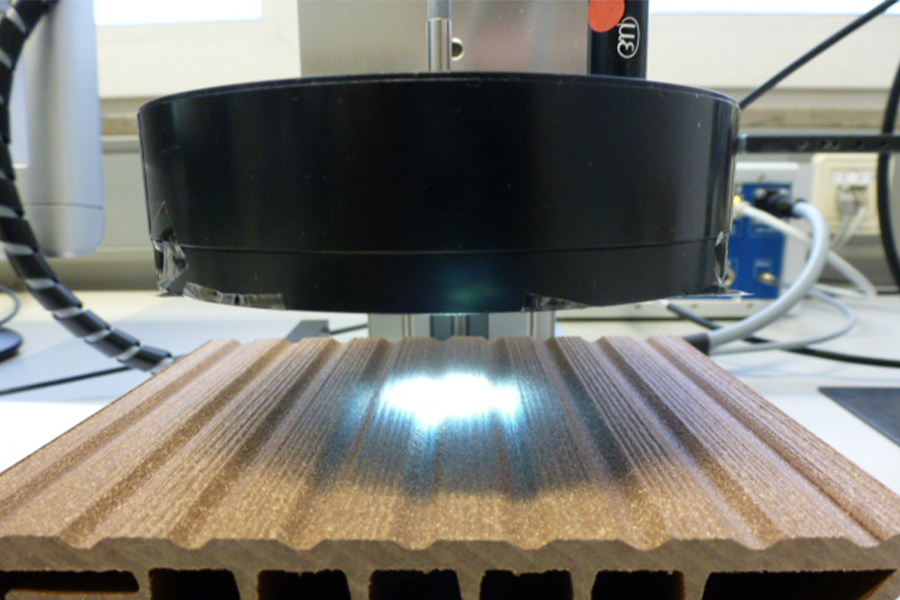

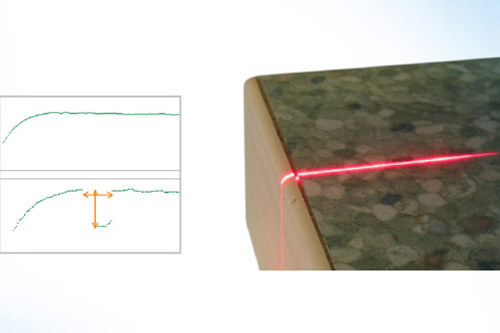

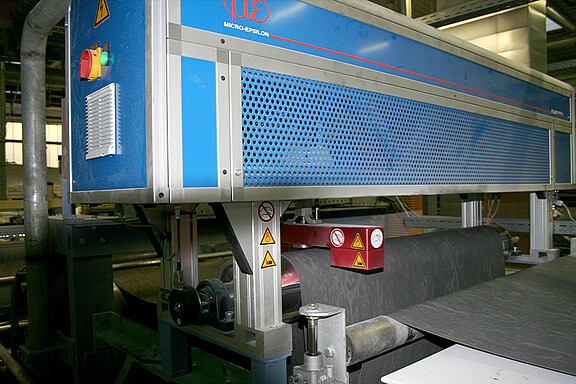

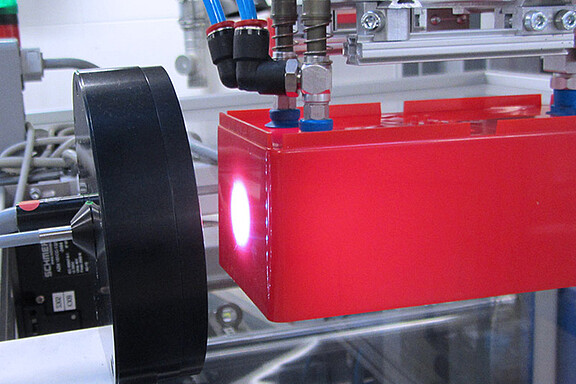

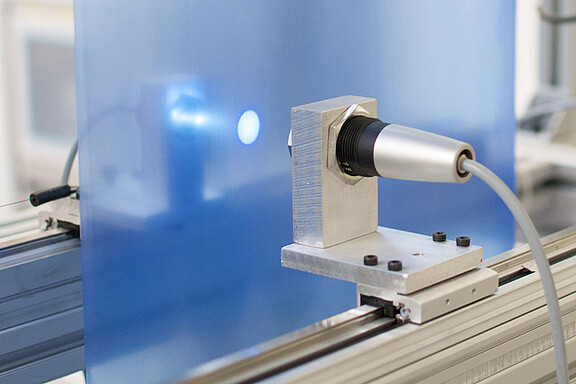

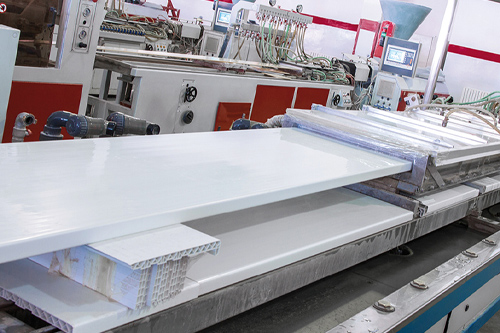

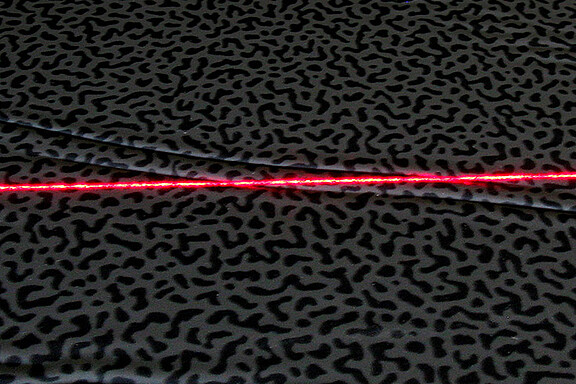

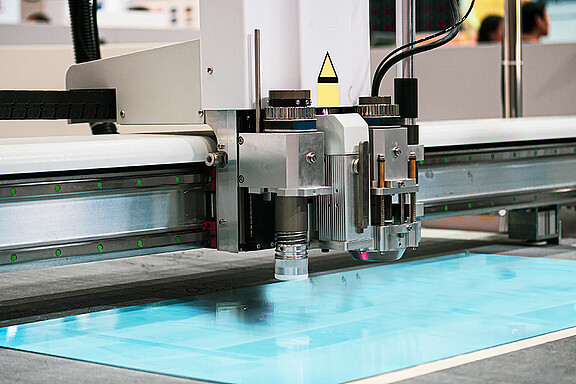

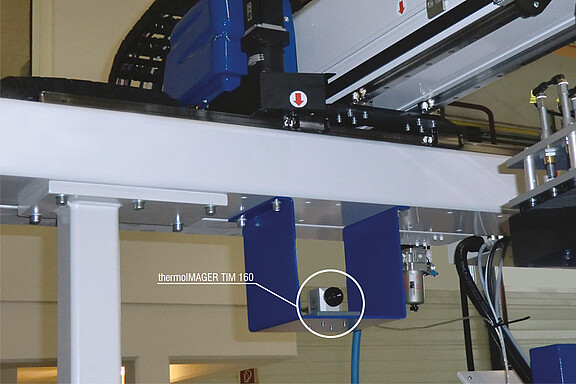

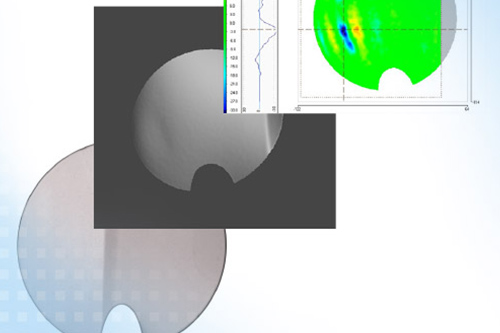

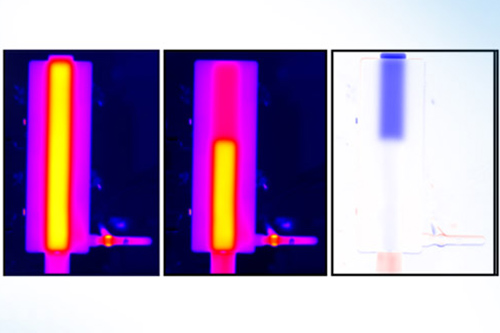

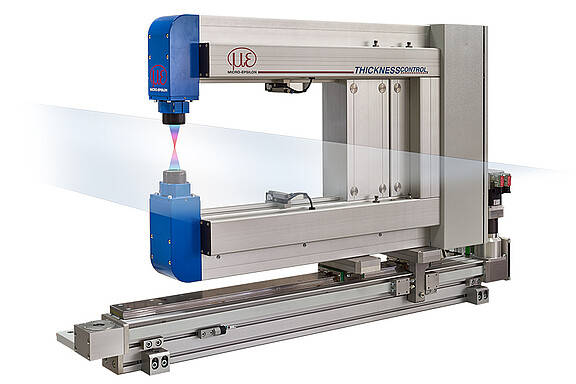

Micro-Epsilon erbjuder ett brett utbud av givare och lösningar för beröringsfri mätning vid plastproduktion. Dimensioner, tjocklek, temperatur, färg och präglingsmönster i rull- eller arkform kan mätas på ett tillförlitligt sätt i ett stort antal processsteg från extrudering via formning till vidare bearbetning.