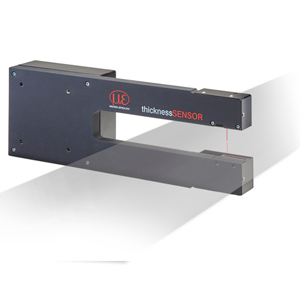

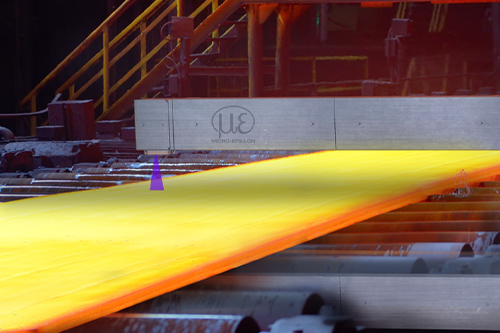

Tillverkning och bearbetning av metall

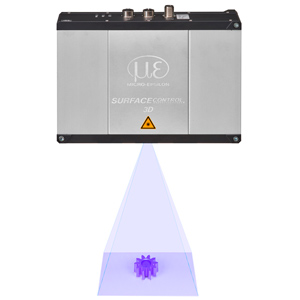

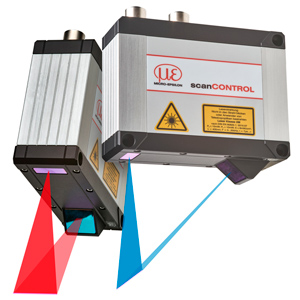

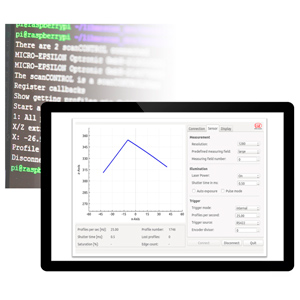

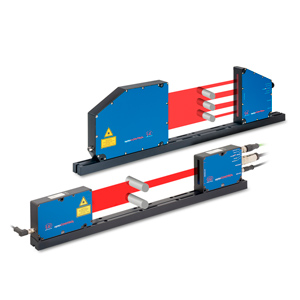

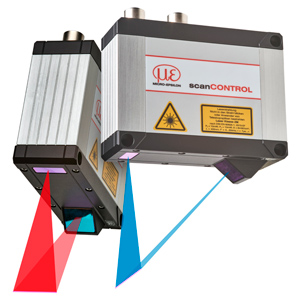

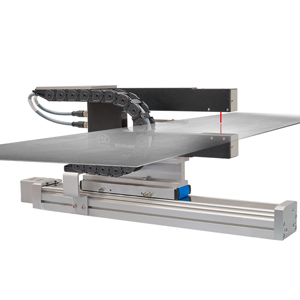

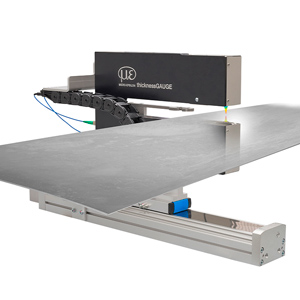

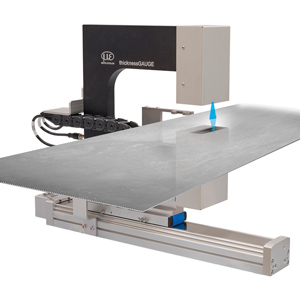

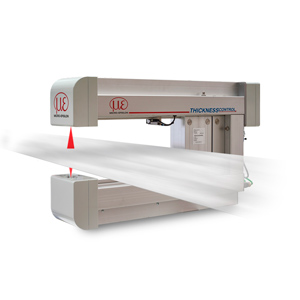

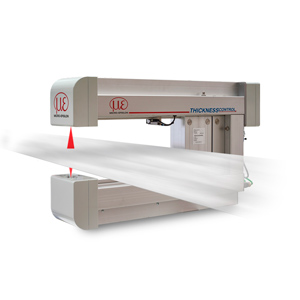

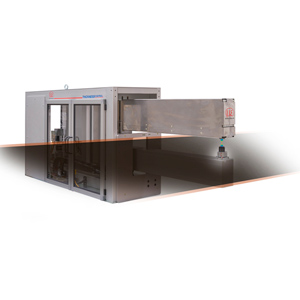

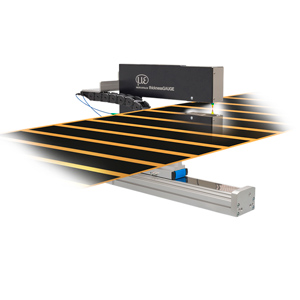

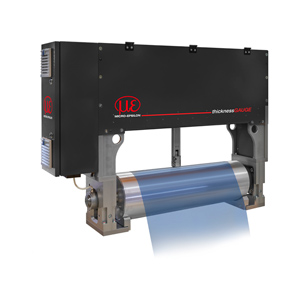

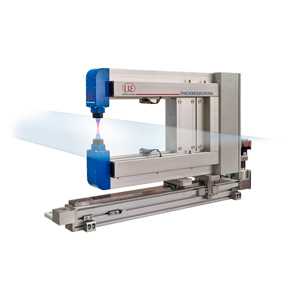

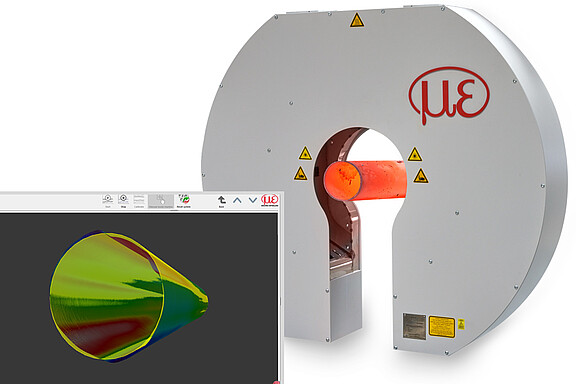

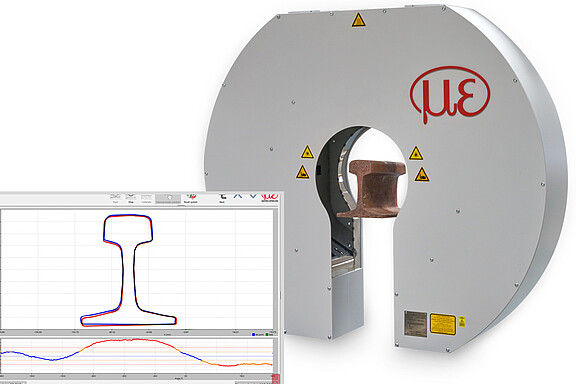

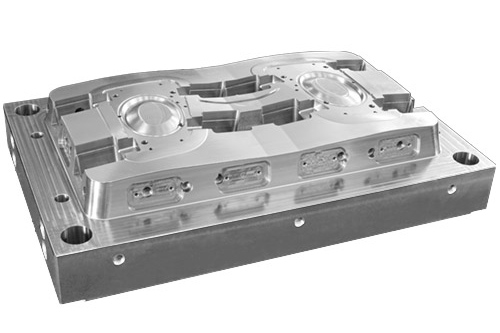

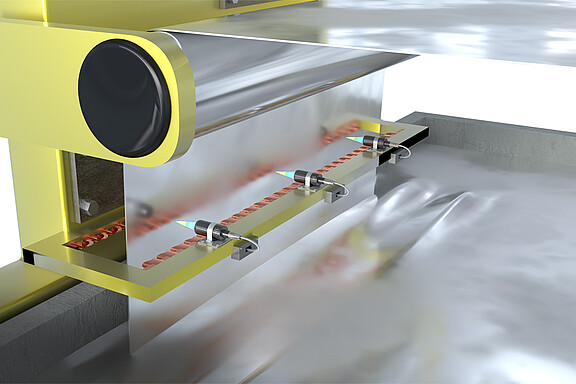

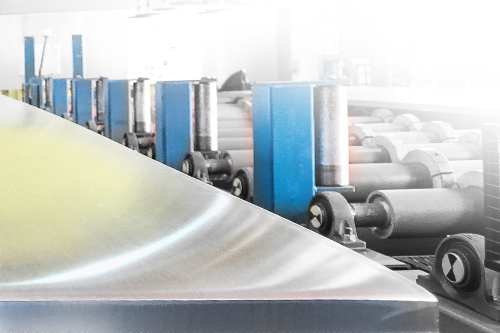

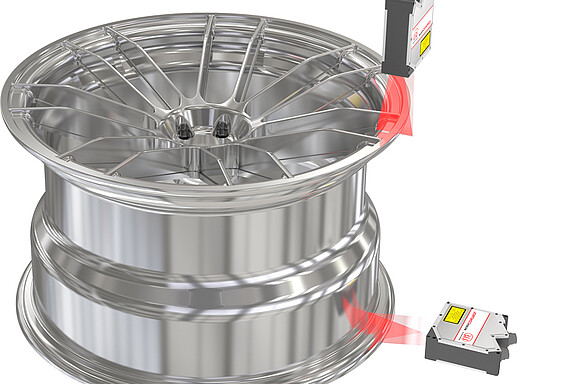

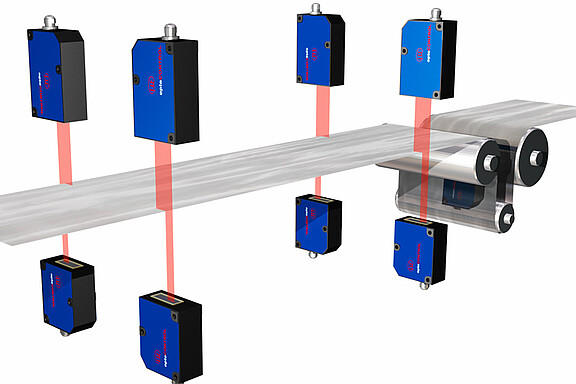

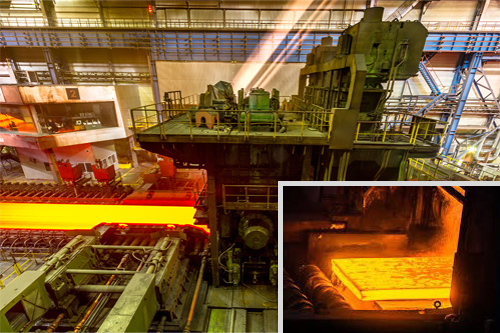

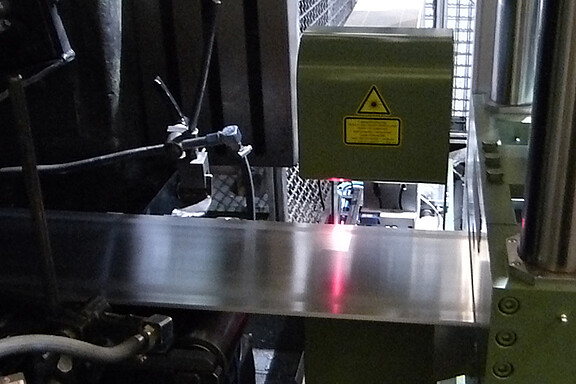

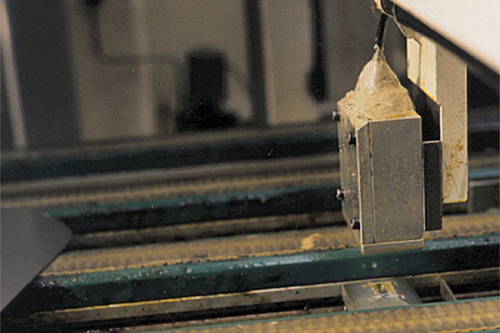

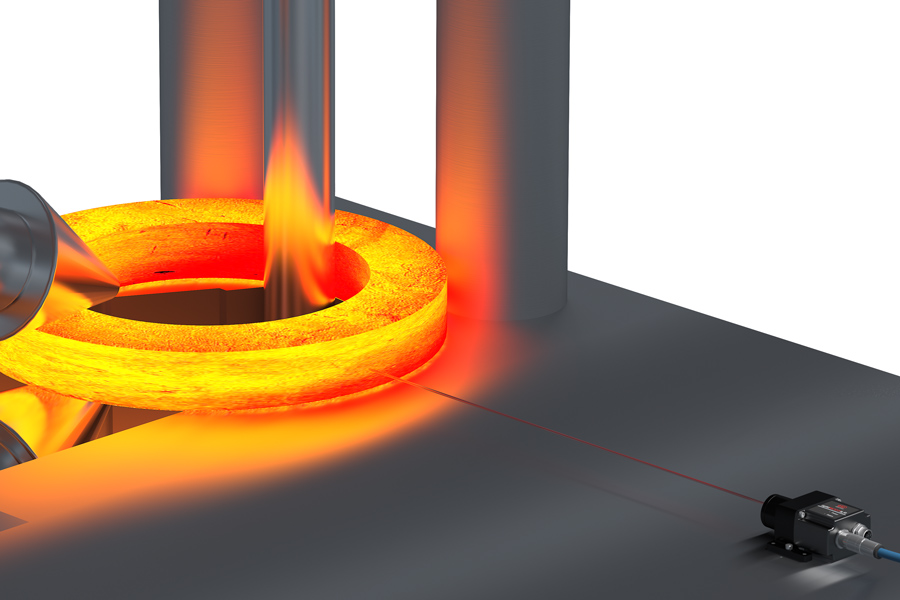

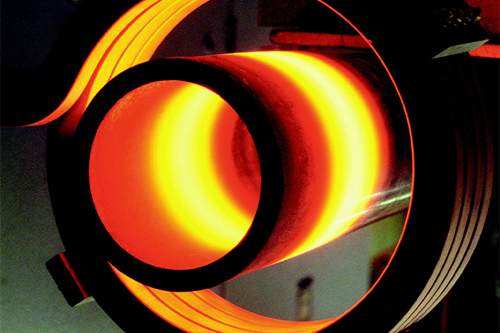

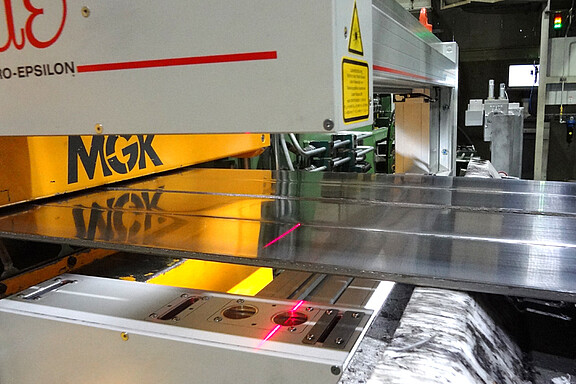

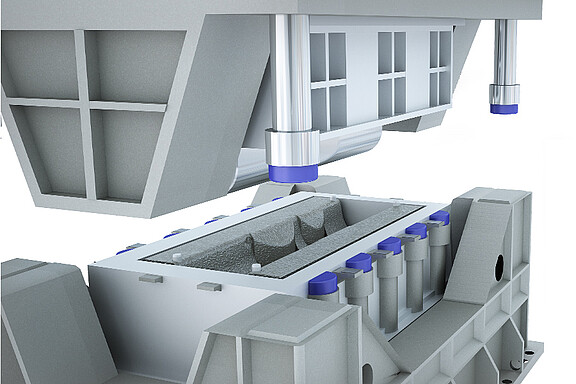

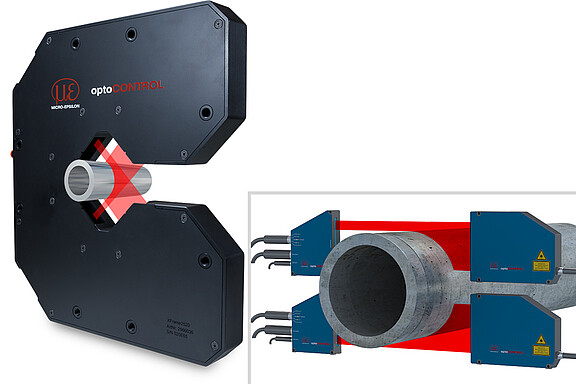

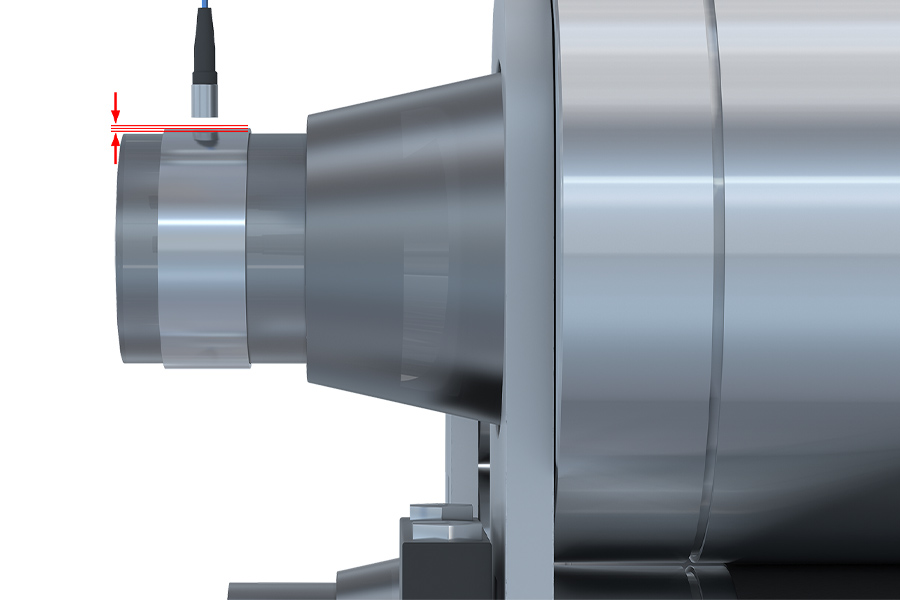

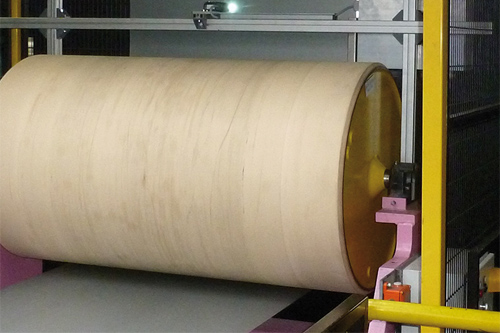

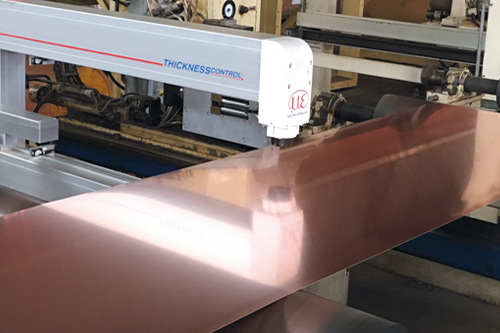

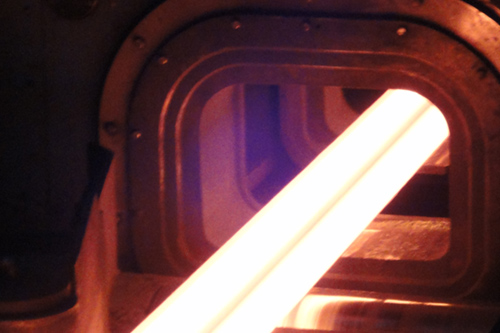

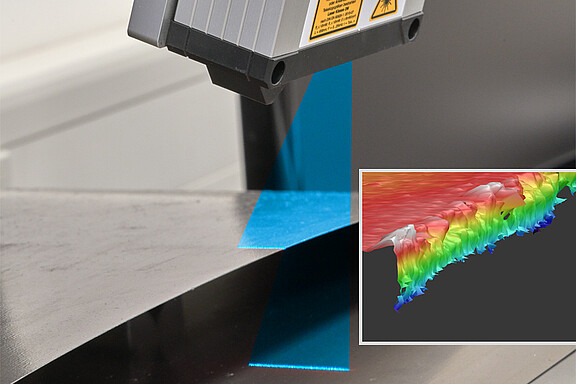

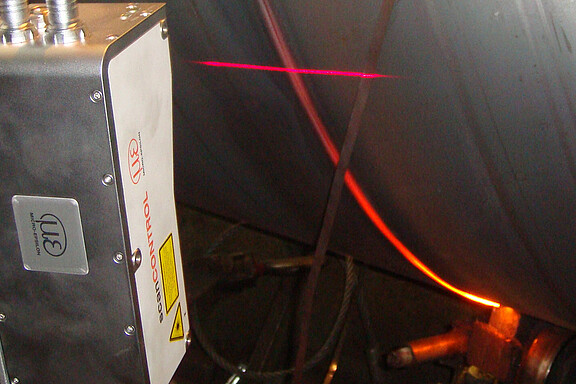

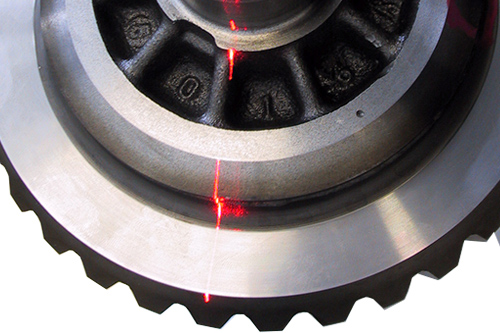

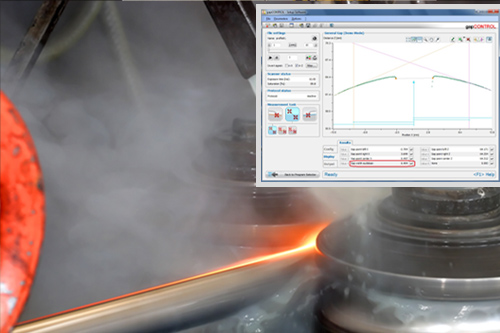

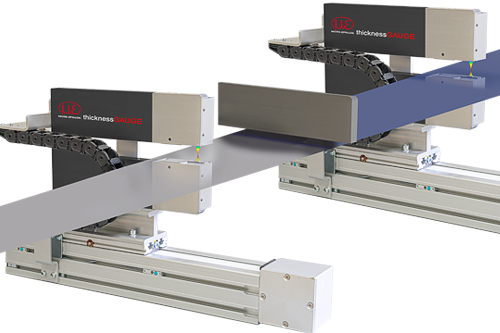

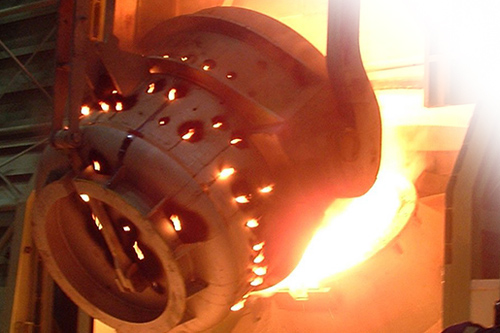

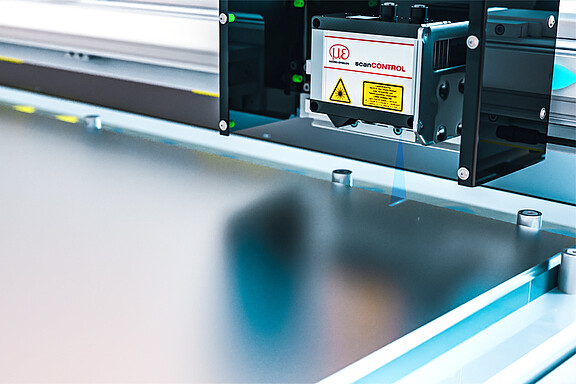

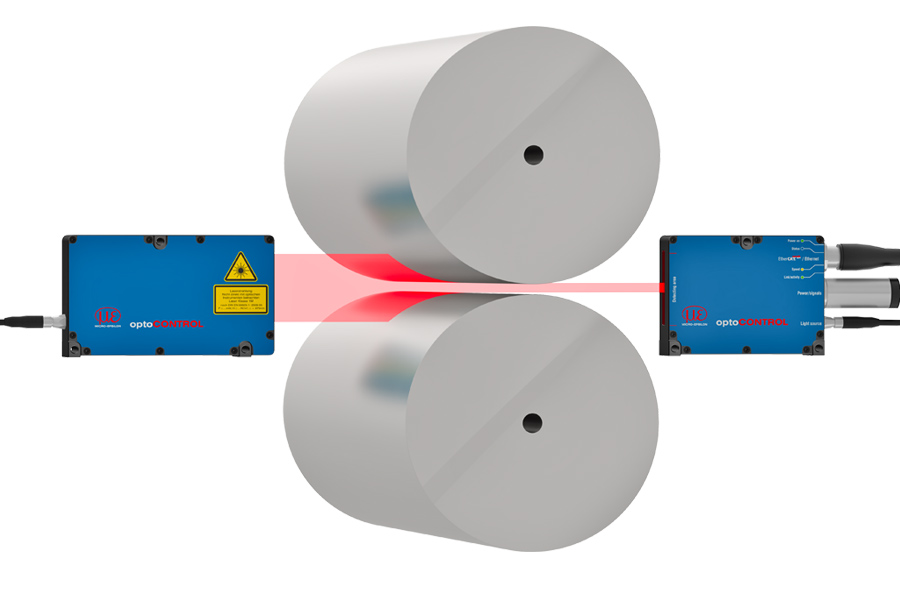

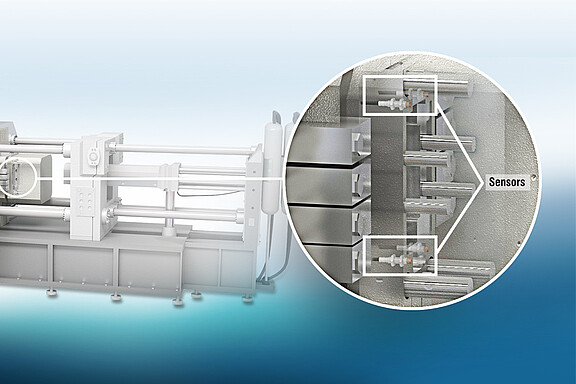

Intelligenta givare krävs på många platser i produktion, bearbetning, transport och lagring av metallmaterial. Här möjliggör givare effektiv och säker produktion samt problemfri bearbetning. Micro-Epsilon har kompetens och kunnande inom ett stort spektrum av applikationer: positionering av kranar, maskindelar och material, övervakning av tjockleken på metallband och plåtar samt profilmätning av pressgjutningar.